Production of electroslag- remelted materials (ESR)

We offer

- ingots in ESR quality,

- forgings in ESR quality,

- remelting of your ingots in the ESR equipment,

- remelting of your ingots in the ESR equipment and reforging in the CKV 2250 and CKV 1600 presses

Installed equipment

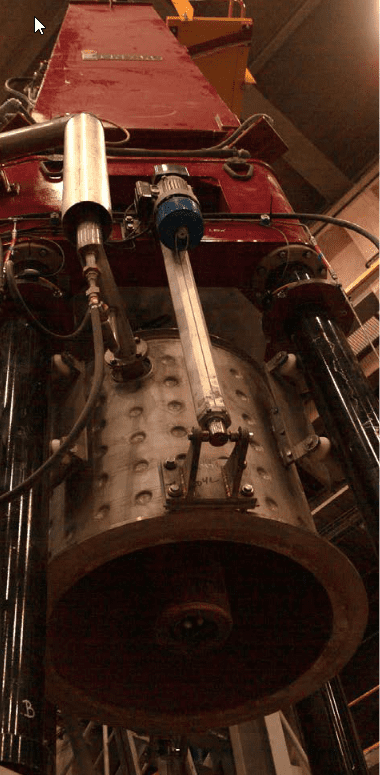

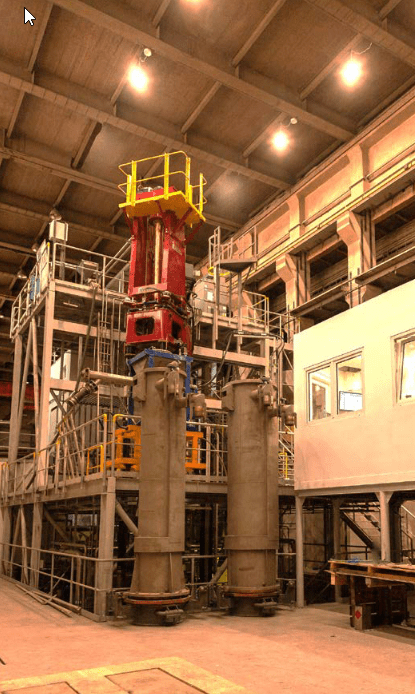

- the ESR with protective atmosphere and active slag (manufacturer INDUCTOTHERM GROUP – CONSARC)

- monthly production of 200 to 250 t

| Parameters of remelted ingots | |

|---|---|

| Diameter | Weight |

| 555 mm | up to 5 700 kg |

| 595 mm | up to 6 500 kg |

| 710 mm | up to 9 100 kg |

Production processes

Electrodes for the ESR are produced in the equipment of primary metallurgy, electric arc furnaces, technology of secondary metallurgy, ladle furnace LF and steel vacuum processing VD/VOD. For remelting, we use cast or forged electrodes.

Special structural steels – rolls for rolling aluminum, turbine rotors, materials for aerospace industry

Tool steels – die materials, steels of tools for pressing

Austenitic steels stabilized with titanium or niobium – fittings, valves

Martensitic steels – blades of turbines and turbochargers

Contact

Jaromír Pospíšil

Commercial Manager of Metallurgical Division

Phone: +420 566 642 405

E-mail: jaromir.pospisil@zdas.cz